문의 보내기

연락처 정보

-

주소

PAIBANG Industrial Zone, Henggang 타운, Longgang District, Shenzhen

-

-

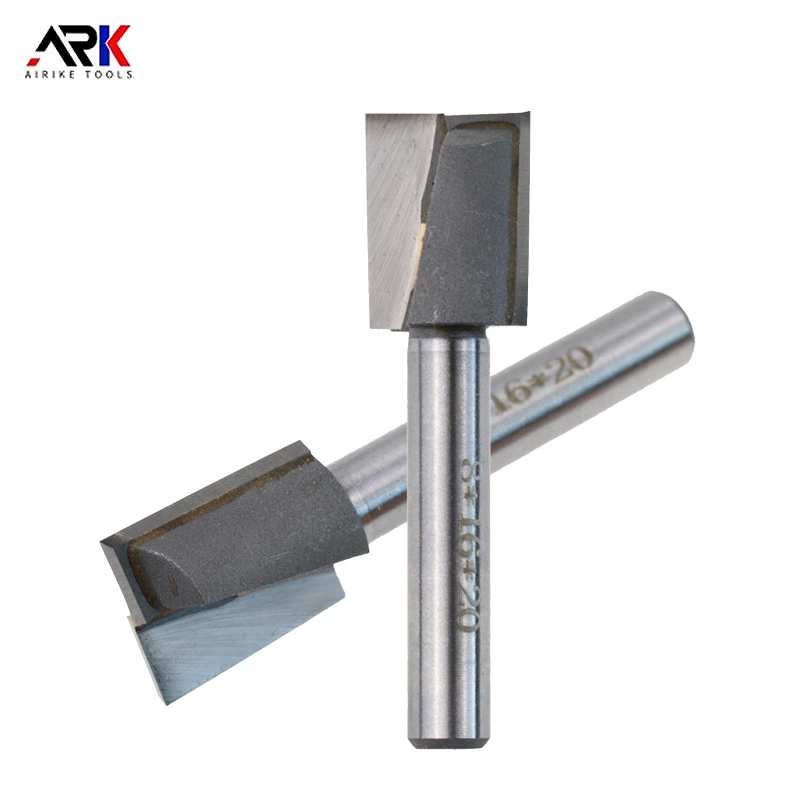

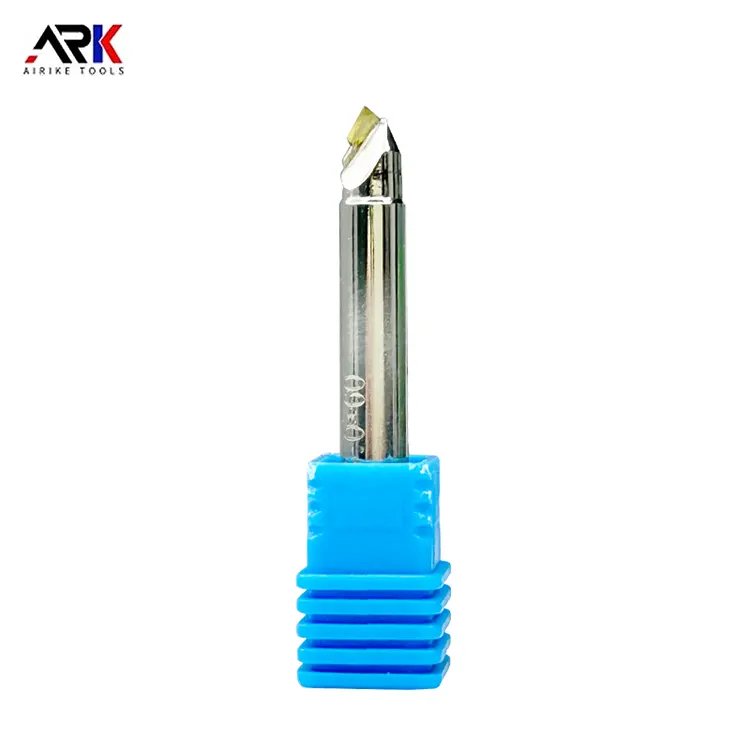

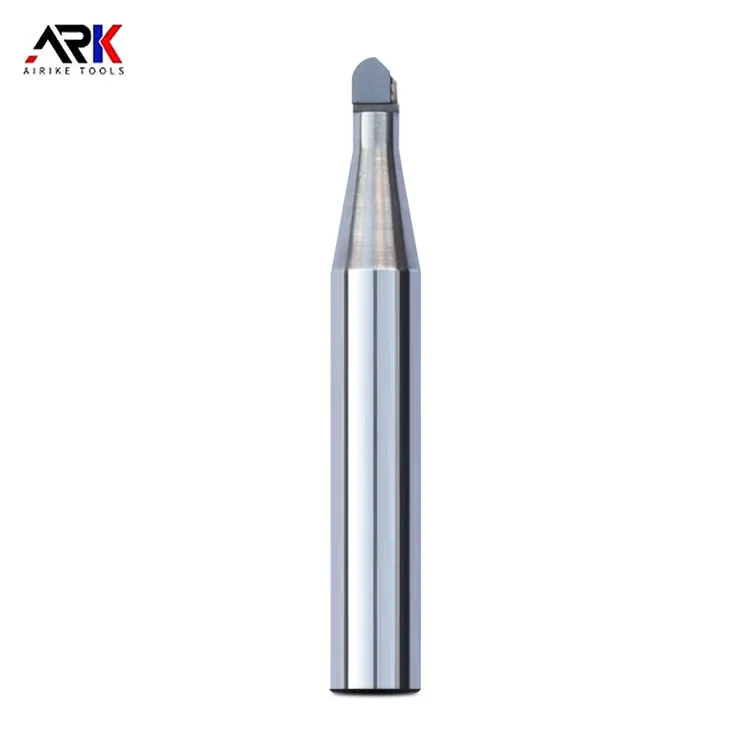

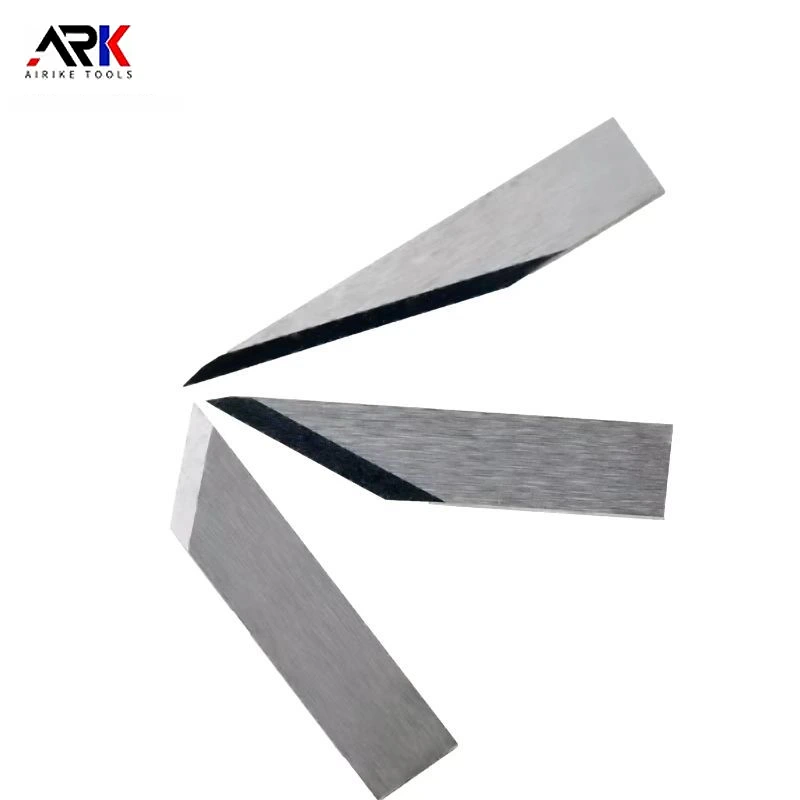

문의를 위해 Zhongyeda 조각 기계 밀링 커터, 목공 밀링 커터, 금속 절단 밀링 커터, 이메일 주소를 우리와 함께두면 24 시간 이내에 연락을 드리겠습니다.